PitSense is a community of people organized to respond to proposals for further increases in the number and size of aggregate operations in Caledon.

We are opposed to the continuing 'Domino Effect' growth of open pit mines and quarries in the agricultural and rural residential areas of the Niagara Escarpment and UNESCO World Biosphere Reserve.

You can't keep doing the same thing and expect different results.

Copyright © 2010-2024 PitSense Niagara Escarpment Group Inc.

All rights reserved

A L T E R N A T I V E S P.1 click HERE for P.2

Our awakened environmental concerns and our new awareness of the costs, both social and economic, of the traditional relationship between the Aggregate Industries and society require us to do some fundamental re-thinking. Pitsense believes that a new and comprehensive Model for Aggregate Extraction needs to be developed. Following is the beginning of a proposal that would address many of our concerns ...

Processing and Transport.

Rationale:

Aggregate pits and quarries, numbering in the thousands, are scattered haphazardly throughout Southern Ontario with little regard to integrated planning or negative impacts on communities and the environment.

New applications frequently come as a complete surprise to local residents, and their subsequent efforts to protect neighbourhoods, wetlands and other sensitive areas from these intrusive operations are too often unsuccessful.

The model proposed would do away with the present sporadic patchwork pattern of excavation operations, and would instead locate all future pits and quarries in areas where environmental and human health is least affected.

This new geographical pattern of excavation sites would depend on proximity to railway lines.

The mode of transport for all medium and long distance hauling would be by rail to strategically located “Transfer Stations”. Only short hauls from there to work sites would be by truck.

The total number of new pits and quarries would be significantly lowered.

The scale of each operation would depend on demand.

The proposed changes would reduce the legal and the logistical complexity, the workload for inspectors and the total environmental impact.

This Model strives to achieve the following goals:

· Preservation of the natural environment

· Preservation of aggregate resources

· Preservation of clean ground and surface waters

· Preservation of clean air

· Quiet operations

· Safer roads with less wear from heavy truck traffic

· Comprehensive and objective long term land use planning

· Reduction of cost to resolve disputes

· Less economic loss to property owners and municipal governments

· Pricing of aggregates that reflects the total real cost to the natural environment and to society

The above goals do not differ much from goals stated in the Provincial Policy Statement (PPS) and the Aggregate Resources Act (ARA), but there is an absolute change in approach and implementation.

The main changes concern:

1. Criteria for choice of location

2. Control and ownership of land used for pits and quarries

3. Depth and design of excavation

4. Design of processing facilities

5. Water (Permits to Take Water - PTTW)

6. Type of equipment

7. Mode of transport

8. Transfer stations

9. Pricing

1. Criteria for choice of location.

It would be the public’s (government’s) responsibility to take a leading role in selecting the land used for extraction, and the following concerns would be thoroughly and conscientiously implemented.

Concerns:

· Wildlife

· Ecology

· Water

· Air

· Aesthetics

· Agricultural Potential

· Recreational Potential

· Developmental Potential other than Extraction

· Proximity to Rail

· Proximity to local, regional or Provincial Market

· Local Community’s Needs

2. Control and ownership of land.

The operators would not need to own* the land to be excavated.

The Public would have control over land to be excavated.

Operators would follow preset conditions as laid out in a publicly disclosed contract.

Conditions:

· Operators would prepay, or by other means be responsible, for full rehabilitation and have insurance against mishaps

· Evaporation would be the major loss of water

· Fines would be utilized in an environmentally friendly manner

· A complete** set of core samples with independent third party analysis would pass public scrutiny*** prior to any new section being quarried

· Site plan area and depth design and Category of excavation could not be amended without a new licence application.

* Too often have OMB chairs let ownership trump good common sense (as was the case in Michipicoten )

** Degree of completeness here depends on the likelihood of finding deleterious matters (as in acid mine drainage)

*** Core samples and assays would be sent to MNR for approval, and an FOI request would not be needed for members of the public to gain full access and copies of the day to day approval process.

3. Depth and design of excavation

Depth of design for sand and gravel pits would remain no less than 2m above established groundwater level.

Depth of design for limestone and dolomite excavation would remain no less than 2m above established groundwater level except in underground aggregate excavation.

Underground aggregate mining would be designed to prevent any accumulation or seepage of water.

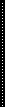

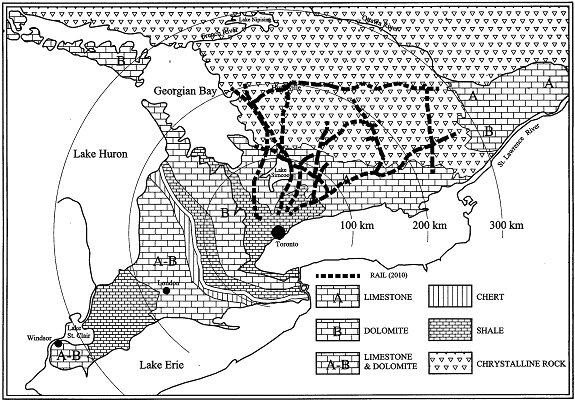

Depth of design for crystalline rock quarries (Precambrian Shield Fig.1) would remain no less than 2m above established groundwater level unless the operation did not interfere with groundwater quantity or quality.

Fig.1

4. Design of processing plant

The objective would be for all crushing, screening and washing of aggregates to be done in an enclosed facility with negative air pressure. Fines would be removed from the enclosed air through washable filters.

All fines from the washing of aggregates and air filters would be utilized, and the water reused for washing.

Aggregates would move to and from processing plants via enclosed conveyors.

5. Water

Presently, millions of litres of water are pumped daily to dewater pits and quarries in Ontario.

A preferred model would require each operation to be located and designed so that daily dewatering would not be needed.

Fines in water used to wash aggregates would be separated in sedimentary ponds (or other similar structures). The water would then be reused for washing aggregates.

6. Type of equipment

Electricity from hydro (not onsite diesel generator) would be the preferred power source.

All diesel engines on site would be high efficiency (common rail fuel system or equivalent) and run on low sulphur diesel fuel. Presently 12 parts per million qualifies as low sulphur, and is required for all on road diesel powered vehicles.

All hydraulic fluid used on site would be classified in an environmentally friendly category. Presently non-mineral based highly biodegradable hydraulic fluids are at the leading edge both for performance and low environmental impact, and cleanup after a spill is less costly due to the high level of biodegradability.

7. Mode of transport.

The last 20 years have seen a considerable increase in truck traffic while rail transport has been reduced. This proposed model would contribute towards reversing this trend.

All medium to long distance hauling of aggregates would be via rail (Fig. 2) and not by truck.

8. Transfer stations

Ontario needs to reconsider some major planning issues with regards to “Places to Grow”. Urban Sprawl is not sustainable. We need to plan for higher urban density, and such a plan should include a network of aggregate transfer stations strategically placed and connected to rail.

Many communities were built near the railways, and the building material came from supply depots near railways. It would be reasonable to follow this concept with regards to a future aggregate transfer station network.

Fig. 2

(Fig. 2 only shows rails north of Toronto and south of Parry Sound in or near the Precambrian Shield)

9. Pricing.

The present f.o.b. (freight on board) price per tonne of aggregate is very low. However when we begin to include the costs to property owners, municipalities, human health, the environment, and society in general, resulting from each tonne of aggregate produced and delivered in Ontario, then the overall cost becomes much higher.

This model would allow us to better manage and prevent negative environmental and economic impacts. Yet it would probably not increase the all inclusive cost of producing aggregates.

· Environmental impact would be reduced.

· Economic costs could be reduced and would be more fairly distributed.

· The cost to human health would be reduced.

· Reuse and recycling of aggregates would become more viable.

PLEASE NOTE: These proposals are preliminary and require further study and refinement.

All stakeholders need to get involved in order to identify and resolve all issues.

PitSense gratefully acknowledges the work done by Torfinn Hansen on these proposals.

PitSense believes that we must re-evaluate society's relationships between our

aggregate industries, our aggregate users, our environment, and ordinary citizens

who currently suffer the harmful consequences without adequate compensation.

We must create a better balance between all stakeholders.

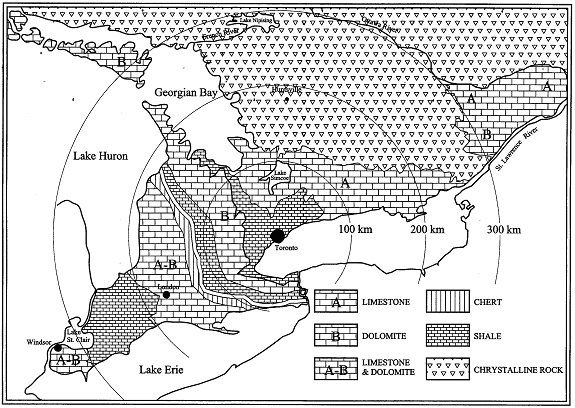

Learn from the past and present to create the future you want. Alternatives do exist. We just need to identify them, advocate for them, and demand them from those who have the responsibility for creating the legislative and regulatory environment needed to foster change. There are both short-term and long-term alternatives to the way the aggregate game is being played out. One exciting alternative involves reducing the demand for aggregates. Presently, large quantities of aggregate, and oil, are consumed by building and maintaining asphalt highways. If we could seriously curtail that demand, how good would that be? If we could generate electricity AT THE SAME TIME, and thus have the highways pay for themselves, it really gets exciting! Take a look at this video and sit back and imagine the possibilities.

This is really 'moving out of the stone age' ....

http://www.wimp.com/solarhighways/

Also see: http://www.solarroadways.com/highway.shtml

and: http://www.autoevolution.com/news/solar-highways-23741.html

When dealing with a NON-RENEWABLE resource such as aggregates, sooner or later we must develop and adopt alternatives. At present, we are depleting these resources more quickly than necessary, in part because the fundamental economics are skewed. PitSense believes society is subsidizing the extraction and consumption of aggregates purportedly for the benefit of society, but also for the benefit of profitable corporations. These operations are too often conducted at the expense of neighbouring property owners and municipal taxpayers, who go uncompensated when property equity is eroded and tax levies on tonnage are insufficient to cover maintenance costs on infrastructure. If legislative and policy changes were to address these inequities, we believe it would go a long way to stimulate the development and adoption of alternative materials and greater recycling.

In 2005 the the Pembina Institute and Professor Mark Winfield PhD. published a study entitled "Rebalancing the Load: The Need for an Aggregate Resources Conservation Strategy for Ontario". He stated: "The current, extremely low resource charge regime, under which, as the ministry notes in its response there has been no increase in provincial royalties for more than thirty years, on the other hand, provides no incentives to ensure the efficient use of the resource." Our PitSense initiative to implement 'Full Cost Accounting' will help to remedy this imbalance. Please see the full Pembina report HERE.

Future Roads - smooth, durable, illuminated, energy-producing marvels

will pay for themselves!

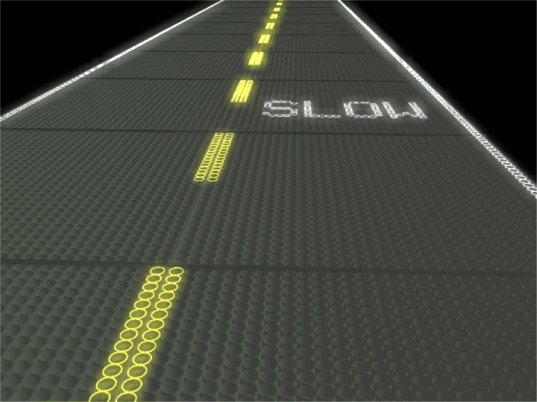

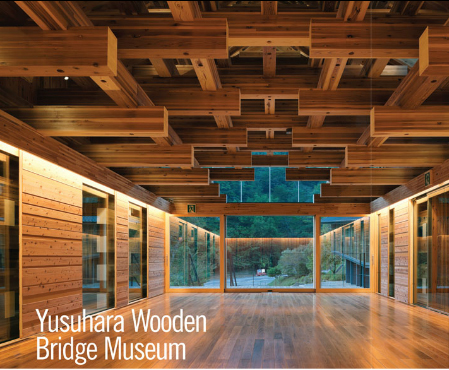

Imagination is the key to the future. Technologies exist that will enable us to reduce our wasteful consumption of aggregates and their by-products. A recent article in the Globe & Mail newspaper discusses substituting wood products for concrete in construction. "Five years ago, tall wood buildings (those six storeys and higher), were not even on the radar for architects, engineers and developers in Canada. But since the idea has caught on in Europe and Australia, and boasts distinct environmental and economic advantages, it is slowly gaining ground."

All we need is political leadership that will allow our imaginations to flourish, unhindered by old ways of thinking and entrenched special interests.

Photos:

Wood Design & Building Magazine / Canadian Wood Council

New (old?) Technologies Pointing the Way Forward

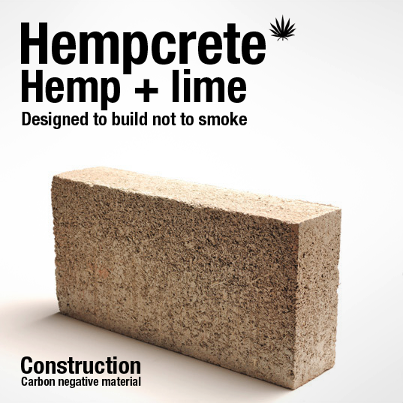

A recent and promising construction technique will provide an opportunity to utilize a low-carbon, low-energy, cost-competitive substitute for concrete. It is HEMPCRETE - already proven in a number of buildings in several countries. It is time for us to push for adoption of this technology and adaptation/updating of our building codes and laws regarding the use of hemp composites.

Learn more at: http://www.hemp-technologies.com/

Interestingly, almost 75 years ago Henry Ford produced a car made from hemp.

Isn't it time we caught up and left stone-age attitudes behind?

Changes to the ARA have been recommended in the STANDING COMMITTEE ON GENERAL GOVERNMENT REPORT ON THE REVIEW OF THE AGGREGATE RESOURCES ACT. The changes are modest, and generally favour the aggregate operators over the public, but we need to recognize progress when it occurs. PitSense applauds a recommendation regarding alternative transport methods. Help us encourage action by government and industry.

The report said: " The Committee believes that the increased use of marine transport and the possible use of rail transport in the aggregate and related-cement and asphalt industries would be advantageous with respect to community impacts and offer environmental benefits, especially within or on the fringes of the Greater Toronto Hamilton Area. The Port of Hamilton, Canada's busiest port on the Great Lakes, has longstanding experience in moving bulk commodities.30 Without detracting from the "close to market" principle that informs most aggregate operations in southern Ontario, the Committee believes there should be a priority review of enhanced opportunities for marine and/or rail transport of aggregate materials within Ontario." which led to the following recommendations:

34. The Ministry of Natural Resources, the Ministry of Transportation and the Ministry of Infrastructure should commission a technical study of the opportunities available in Ontario to utilize alternative water and rail modes of transport to move aggregate materials, drawing upon the experience of other North American jurisdictions.

35. The Ministry of Natural Resources, the Ministry of Transportation, the Ministry of Infrastructure and the Ministry of Economic Development, Trade and Employment should conduct a comprehensive inventory analysis of where raw aggregate and associated cement and asphalt products are being transported by marine transport within Ontario to determine whether such operations might be readily expanded for broader use by the aggregate industry. Appropriate consultations should be held with aggregate and shipping operators who utilize or provide these services.

36. The Ministry of Natural Resources, the Ministry of Transportation and the Ministry of Infrastructure should seek to implementpilot project(s) on a priority basis to utilize the rail and/or marine modes of transport to transport aggregate materials and products. The development of a rail corridor to the north of the Greater Toronto Area should be examined as a priority. Financial or tax incentives to support such pilot projects should be considered.

37. The analyses undertaken pursuant to recommendations 34-36 should result in a report, prepared jointly by the Ministry of Natural Resources and Ministry of Transportation, with input from other relevant Ministries, containing recommendations on how to expand the role of the rail and marine modes of transport in the movement of aggregate and associated bulk materials within Ontario.